Maximizing efficiency: the essential guide to timely liner changes – Part 2

Why and how to change liners at the right time, improving animal health and milking speed.

In the previous episode, we demonstrated the fundamental role that liners play in maintaining a good teat integrity and what the right timing to change them is.

However, underestimating liner replacement is also a concern for milking speed, as we will show in the next lines, along with some advice on how to change these components more quickly and efficiently.

Teat integrity and milk speed

Along with affecting the teat integrity, also milking speed is jeopardized. In fact, further typical consequences of worn liners are:

Decreased peak milk flow rate, slower milking, and longer unit on time.

Increased vacuum fluctuations and more liner slippage.

Inefficiencies in collecting milk, leading to incomplete milking.

If you are still not convinced about how important changing liners at the right time is, here’s what Sunita McGrath BVSC, Senior Vet and Co-owner of VetSouth New Zealand, stated:

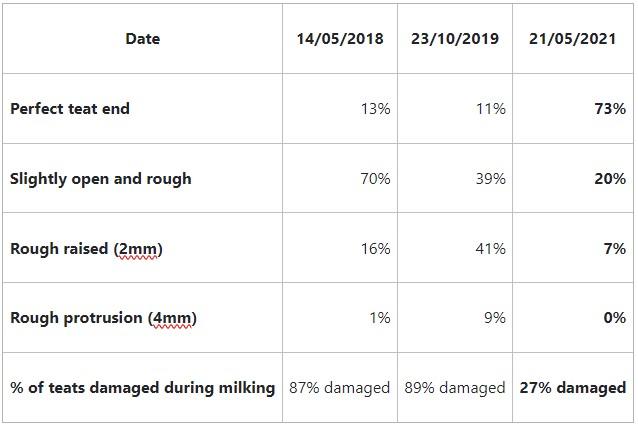

“Farmers think they only have a few cows with teat-end damage. I know it is going to be bad or potentially horrendous because while they notice dry or cracked teats, they struggle to assess proper teat-end health.

Mastitis is multi-factorial, but if farmers want to get that SCC down and improve teat-end health, then regularly changing their liners is definitely something I’d recommend. If you do not have good teat health, you will have mastitis.

The teat-end damage from ineffective liners is probably the biggest concern.”

Liner replacement can be more efficient!

Keeping track of the number of milking and the time required to change liners can be discouraging, leading to postponing the service and over-using the components.

Even if this decision seems harmless, every milking session with worn liners is a potential risk for animal health and farm profitability.

In fact, when mastitis spreads, not only does it entail higher antibiotic and vet expenses, but it also causes a loss in milk produced and higher labour costs.

To avoid all this, a good ally could be a rental service, that allows you to receive your liners or clusters at your farm and at the right time, ready to be set up shortly and efficiently, as the results achieved by the Caulston Farm (UK) show.

The farm is 600 cows strong, milking twice a day using a 48/96 swingover milking parlour. The farm produces an average yield of 5,300kg and can milk around 300 cows an hour.

In early 2020 the farm owners Adam and Holly decided to sign up to use MI Cluster Exchange Service and started to use triangular vented liners. Since then, the farmers have:

Improved teat-end conditions:

Improved SCC, from 220 to 140.

Decreased mastitis cases, from 40 cases/100 cows to 18 cases/100 cows.

Improved cow comfort. From lots of cow padding and kicking off the clusters, to more settled and relaxed cows.

More time to spend on the farm. Now that clusters arrive assembled, the farmers gain more time to focus on other jobs.

To conclude, even though changing liners is a tiring activity, apparently without any added value, remember that every milking led with worn liners threatens your farm's profitability. So, make sure to regularly change your components and don’t miss our next Blog episodes, to further elevate your milking experience!